POP System POP System |

|

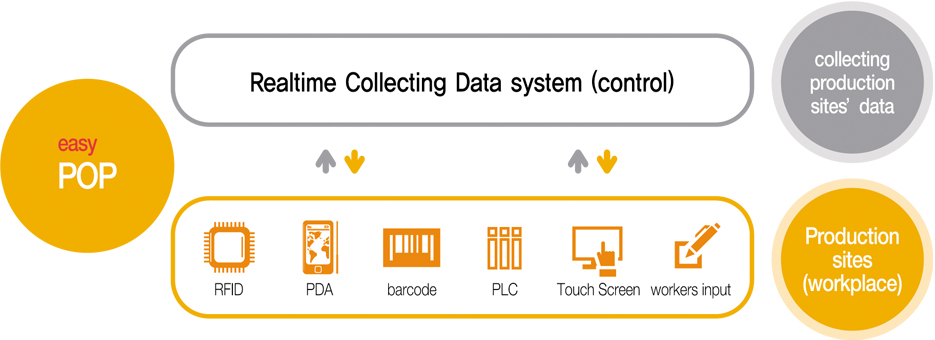

This is Realtime manufacturing, production timing managing system which makes it possible to collect, aggregate, look up all the information or data gotten by production site in real time.

It is a “solution” that can aggregate, analyze, look up the actual states of production information by manufacturing lines or processing such as performance to plan, stock, supply, due-out, quality information/ downtime information, etc.

|

|

|

|

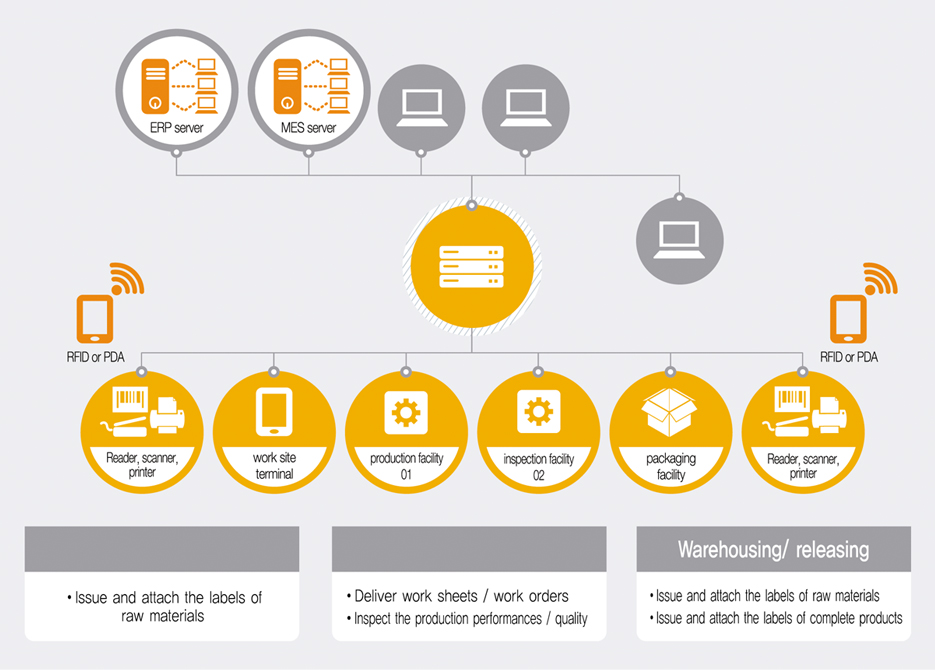

System Diagram System Diagram |

|

|

|

POP System Processing Screen POP System Processing Screen |

|

|

|

The Effects of introduction for POP System The Effects of introduction for POP System |

|

|

|

- Standardization of work

- Decrease in producing need time and improvement in the rate of meeting delivery date

- Improvement in the rate of profit through controlling the manufacturing cost and utilizing resources optimally

- Improvement in cash flows by decreasing stock of raw materials, supplies and inventory of complete products

- Optimization of members and facilities and Improvement in operation of facilities

- Management of orders with the production situation grasping the best production capacity

- Management of processing performances in real time and the reason of production bottleneck in real time

- Tracking management of all the production materials

- Coincidence of distribution and data information

|

|

|

|